Samuel Brandt bought the steamship hull sections in Omaha for $11 in April 1879. And by the time he’d hauled them 300 miles to his homestead in the Dakota Territory, every settler within 50 mi thought he’d gone completely insane. The sections were curved iron plates originally destined to be riveted together as the hull of a Missouri River steamboat.

The shipyard had gone bankrupt after a fire, and the half-finished hull had been cut apart and sold as scrap metal. Most people bought the pieces to melt down for farm implements or to patch equipment. Samuel had different plans. He was going to use them as a roof. Samuel was 41 years old, a German immigrant who’d arrived in New York with his wife Greta and their two children in 1867.

They’d worked in a textile mill in Pennsylvania for 8 years, saving every penny until they had enough money to file a homestead claim and head west. They’ chosen Dakota Territory because land was still available and cheap, and because Samuel had heard that winters there were harsh, but the soil was good. What he hadn’t fully understood was exactly how harsh the winters could be.

Their first winter, 1877, they’d lived in a saodi, a house built from blocks of prairie sod stacked like bricks. The soda had kept them alive, but barely. It leaked when it rained. Mice and insects lived in the walls. The roof, made from cottonwood logs covered with more sod, had sagged under the weight of snow and nearly collapsed twice.

Their second winter, 1878, Samuel had built a proper cabin from milled lumber he’d bought in Yankton. The cabin was better than the Saudi, but had its own problems. The wood was green, not properly seasoned, and had warped as it dried, creating gaps between the boards. Wind came through those gaps like water through a sie.

They’d stuffed the cracks with cloth and mud and prairie grass, but it was never enough. When the temperature dropped below zero, frost formed on the inside walls. When it dropped below 20 below, the frost was an inch thick, and Dakota Territory winters regularly hit 40 below. Samuel had watched his children shiver through two winters, had seen his wife’s hands crack and bleed from the constant cold, had felt his own lungs burn with every breath of the frigid air that invaded their cabin.

No matter what he did, he’d watched neighbors lose fingers and toes to frostbite. He’d attended the funeral of a family who’d frozen to death when their cabin’s roof collapsed under snow and they couldn’t dig themselves out. Something had to change. The traditional methods weren’t working. Wood cabins weren’t built for Dakota territory cold.

Saudis leaked and collapsed. He needed something different. The idea had come to him in March when he’d been in Omaha buying seed and supplies. He’d seen the curved iron plates stacked at the defunct shipyard, noticed how they were designed to overlap and shed water, how the metal was thick enough to be structural, but thin enough to be worked.

And he’d thought about how miners sometimes used corrugated metal for mine roofs because it was strong and didn’t rot or burn. What if he used iron plates as a cabin roof? Not instead of wood, but as a protective shell over wood. The iron would shed snow and rain perfectly. It wouldn’t rot. It wouldn’t collapse under weight, and if he curved it properly, it might even redirect wind over the cabin instead of letting it slam into flat walls.

“It was a crazy idea. Everyone told him so.” Iron roof, said Otto Zimmerman, his nearest neighbor, when Samuel explained the plan. In winter, you’ll freeze. Metal gets cold. It’ll make the inside colder, not warmer. I’ll insulate underneath. With what? You’re not rich. You can’t afford fancy materials. Mud and straw mixed with hay.

Same as the soda, but in layers. That’s insane. You’re taking the worst parts of a soda and combining them with expensive metal that won’t work. Just build a better wood cabin, double walls, proper chinking. I can’t afford that much lumber. The iron costs $11 total. I already bought it. Otto had looked at Samuel like he was watching a man dig his own grave.

You bought it already without testing if it would work. It’ll work. You don’t know that. Samuel didn’t answer because Otto was right. He didn’t know. He was betting everything on an untested idea using materials nobody else had tried. If he was wrong, he’d have wasted $11 he couldn’t afford and would have to somehow survive another winter in a cabin that was already failing.

But he’d watched his daughter Anna, who was seven, cough through the last winter with lungs irritated by breathing freezing air for months. He’d watched his son Friedrich, who was five, develop chillblades on his feet from never being truly warm. He’d watched Greta’s fingers bleed from washing clothes in ice cold water because they couldn’t afford enough fuel to heat water.

He was going to try. The work began in late April as soon as the ground thawed enough to dig. Samuel’s plan was to build a new structure from scratch. Rather than trying to retrofit the existing cabin, he’d use the old cabin as a workshop and storage while building the new dwelling. First, he dug a foundation trench 2 ft deep and 8 in wide, forming a rectangle 20 ft x 16 ft.

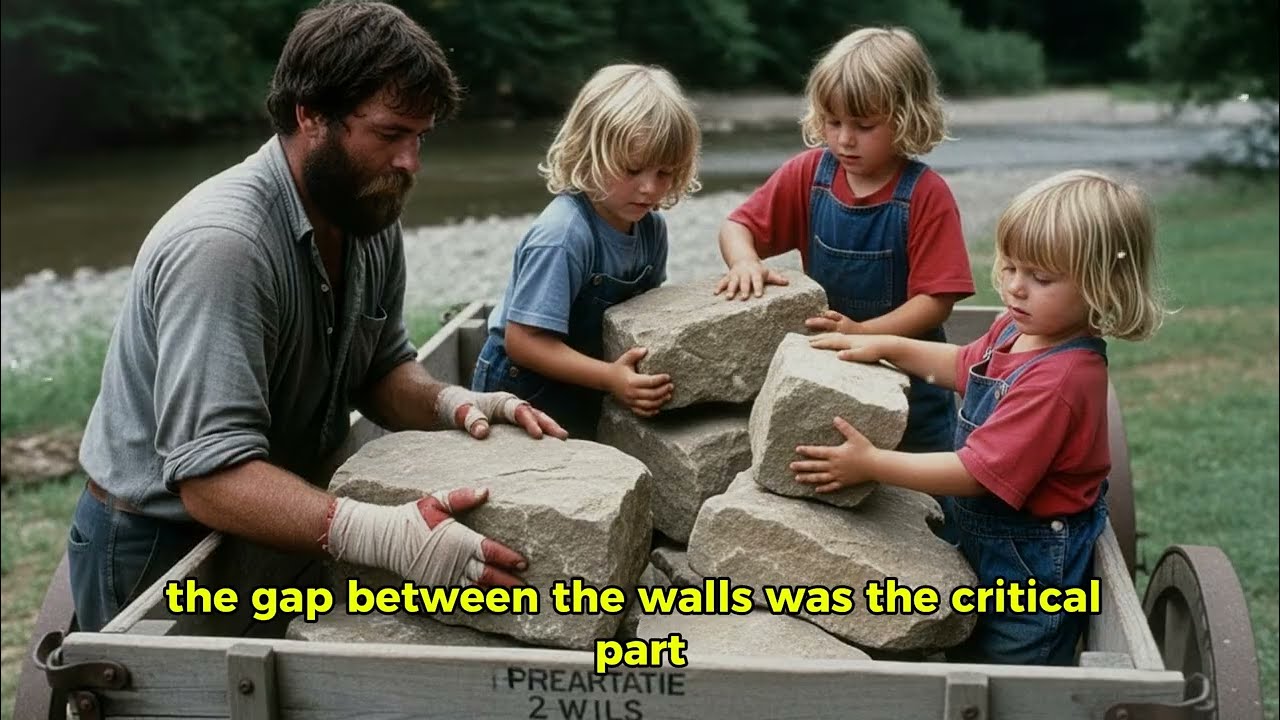

The work was backbreaking. Dakota soil in spring was heavy clay mixed with rocks, and every shovel had to be lifted and thrown. It took him 11 days working sunrise to sunset to complete the trench. He filled the trench with stones hauled from a creek 2 mi away. Each trip with the wagon took 3 hours. He made 47 trips over the course of 3 weeks, loading stones until his back screamed and his hands bled through his gloves.

The children helped, carrying smaller rocks, their small hands getting cut and bruised. Greta watched him work with an expression that mixed concern and frustration. You’re killing yourself for an experiment that might not work. The foundation has to be right. If the structure settles unevenly, the iron plates will buckle and the whole roof could fail.

And if you break your backhauling stones, what happens to us? Samuel didn’t answer because she was right. He was 41 years old and doing the work of three men because he couldn’t afford to hire help. Every night he collapsed into bed with muscles that felt like they’d been beaten with hammers. Every morning he woke up stiff and had to force himself through the first hour of work until his body loosened up enough to continue.

But he kept working because the alternative was another winter in a cabin where his children coughed and shivered despite his best efforts. Then he built walls, but not normal walls. He built them only 5 ft high, much shorter than the seven or 8 ft typical for a cabin. This drew immediate questions from everyone who saw it.

You building a shed? One passing traveler asked. A cabin for who, children? Adults can’t stand up in that. But Samuel’s plan didn’t require tall walls. The walls were double- layered. Inner wall of vertical split logs that he’d spent two weeks cutting and shaping, then a 6-in gap, then an outer wall of horizontal logs.

The gap between the walls was the critical part. He filled it with a mixture he developed himself. Clay mud from the creek mixed with chopped straw, dried prairie grass, and horse manure. The manure was Friedrich’s contribution. The 5-year-old thought it was hilarious to add poop to the walls.

But Samuel had read that the fibrous material in manure actually helped bind the mixture and prevent cracking. The mixture had to be packed in carefully layer by layer, tamped down to prevent air pockets. Air pockets would create cold spots where heat could escape. Samuel spent hours pressing the mixture into the gap, packing it until his arms were numb, checking for gaps by field since he couldn’t see inside the wall once it was closed.

The work took 6 weeks just for the walls. Six weeks of splitting logs, hauling mud, mixing insulation, packing it tight. His hands developed new calluses on top of old ones. A splinter from a cottonwood log went so deep into his palm that Greta had to dig it out with a needle while he bit down on a leather strap to keep from screaming.

The low walls drew immediate mockery from neighbors. Otto Zimmerman rode by one afternoon and laughed out loud. “Building a cabin for dwarfs? Your family going to crawl around on their knees all winter? The height comes from the roof,” Samuel explained through gritted teeth. “The roof? You’re going to make a roof tall enough to stand under?” How? You don’t have enough lumber for a proper pitched roof that high. I have iron. Iron isn’t lumber.

You can’t build rafters out of iron plates. I’m not building rafters. I’m building an arch. Otto had looked at him with an expression that clearly said, “You’ve lost your mind.” But was too polite to say it out loud. The roof was where the iron plates came in. Samuel had purchased 14 curved sections of hull plating.

Each one roughly 6 ft long and 4t wide, curved in a gentle arc. His plan was to create an arched roof by mounting these plates on a wooden frame, overlapping them like scales on a fish, creating a dome that would shed snow and rain, while also adding significant interior height. The wooden frame took three weeks to build. Samuel cut cottonwood saplings and bent them while green, creating curved ribs that spanned from one wall to the other.

He spaced the ribs every 2 ft along the length of the structure, creating a skeleton that looked like an upside down boat hull. Between the ribs, he wo smaller branches and covered everything with a thick layer of mixed mud and straw for insulation. Then came the iron, and this was where the project became truly dangerous.

Each plate weighed approximately 80 lb. Getting them onto the curved wooden frame, which was now 12 ft off the ground at the peak, required help from Otto and two other neighbors who came, despite thinking the whole project was doomed to failure. They had no proper equipment, no scaffolding, no pulley system designed for this kind of work.

Samuel rigged a system using ropes, a cottonwood branch as a lever, and prayer. The process was terrifying. The first plate took them 4 hours to position. They had to lift it using ropes, swing it up to the frame, while Samuel balanced on a makeshift ladder, then hold it steady while he bolted it in place.

The bolts had to go through the iron plate, through the mud insulation layer, and into the wooden rib beneath. Samuel had to drill each hole while standing on the ladder with the 80lb plate hanging over his head, supported only by two neighbors on ropes below. The fifth plate almost killed Otto. They were raising it using the rope system.

Samuel guiding it from above when one of the ropes snapped. The plates swung wildly, crashed into the wooden frame with a sound like a church bell, then fell. Otto dove sideways purely on instinct. The plate hit the ground exactly where he’d been standing, embedding itself 2 in into the hardpacked earth. Everyone stopped working.

Otto sat in the dirt, breathing hard, staring at the plate that had missed his skull by maybe 6 in. “I’m done,” he said. “This is insane. You’re going to kill someone. We need to finish what we started.” “Why? So your crazy experiment can collapse and kill your family in their sleep? This is not worth it, Samuel. Samuel climbed down from the ladder carefully.

He was shaking from the adrenaline. My daughter coughed blood last winter. You saw her blood from her lungs because they were so damaged from breathing freezing air for months. I’m not going through another winter watching my children suffer when I might be able to prevent it. Otto was quiet for a long moment. Then he stood up, brushed dirt off his pants, and picked up his end of the rope.

If another plate falls, I’m walking away, and you can finish this yourself. They didn’t lose another plate, but the work remained terrifying for the next 3 weeks. Samuel developed a system of wooden supports to hold plates temporarily while he bolted them. But every time he climbed the ladder with an 80lb piece of metal suspended overhead, he was aware that one mistake, one broken rope, one rotted wooden rung could kill him.

The plates overlap by 6 in with the overlap facing downward so water and snow would run off rather than seeping in. Samuel sealed the seams with rendered animal fat mixed with ash and crushed charcoal. A waterproofing compound he’d learned from a riverboat captain he’d met in Omaha. The compound had to be applied hot, which meant working with a pot of boiling fat on the ladder while holding onto a plate with one hand. His hands were destroyed.

cuts from the sharp edges of the metal, burns from the hot waterproofing compound, blisters from gripping ropes and tools. Greta wrapped them every night with cloth soaked in salve, but they never fully healed because he was back to work the next morning. Another plate bent when they tried to force it into position on an irregular section of the frame.

The wooden rib hadn’t been curved quite right, and the plate wouldn’t fit without being reshaped. Samuel had to heat the plate over a massive fire, getting it red hot, then hammer it into the correct curve while it cooled. The work required three men with hammers working simultaneously, and if they missed a beat, the metal would cool into the wrong shape.

They ruined two plates completely, bent them so badly, they were unusable. Samuel had to leave them lying in the grass as expensive reminders of his mistakes. iron that cost him nearly $2 lying there as scrap. But after 6 weeks of brutal, dangerous work, the structure was complete. It looked utterly bizarre. The low stone and log walls only 5 ft high, topped with a massive arched iron roof that added another 7 ft of height at the peak.

The iron was rusty red brown, stre with the original black paint that hadn’t quite weathered off. The structure looked like half a barrel lying on its side or like a loaf of bread made of metal and wood. “It looks like a mine tunnel,” Greta said, standing outside with her hands on her hips. “Or a root cellar someone built above ground.

Does it look warm?” Samuel asked, she considered. “It looks strange. I don’t know if it looks warm.” “We’ll find out.” They moved in during the second week of June. The interior was unusual. The arch ceiling created more headroom in the center, but less at the sides. Samuel built the beds along the sides, where the ceiling was lowest, since you didn’t need headroom for sleeping.

He put the table and work area in the center, where the ceiling peaked at nearly 12 ft. The summer proved one thing immediately. The iron roof was an oven. By noon on a hot day, the metal would heat up from the sun, and despite the insulation layer underneath, the interior temperature would climb into the 90s.

Samuel had built ventilation openings at both gabled ends of the structure, but they weren’t enough. I told you, Otto said when he visited in July, metal in the sun. It’s basic common sense. You’ve built a bake oven. It’ll be different in winter, Samuel insisted. If you make it to winter, your family is going to roast first. They survived the summer by spending most of their time outside and sleeping with all the ventilation openings wide.

It was miserable, and Samuel privately wondered if he’d made a terrible mistake. He’d spent $11 on iron, plus the cost of lumber and six weeks of work. and all he had to show for it was a cabin that was cooler in summer than a conventional structure, but still too hot. But he’d built it for winter, not summer.

The real test would come in November. The first serious cold came on October 23rd. Temperature dropped to 18° overnight. Samuel woke to a cabin interior that was 42°. Cold, but not freezing. In their old cabin at the same outside temperature, the interior had been maybe 28°. The difference was noticeable. By early November, nighttime temperatures were hitting single digits regularly.

The iron roofed cabin was maintaining interior temperatures around 35 to 40°, while reports from neighbors indicated their cabins were dropping to 25° or lower. It’s the insulation, Samuel explained to Otto when he stopped by to check on them. The iron keeps snow and wind off the insulation layer. The insulation keeps heat from escaping.

And the arched shape means heat rises and stays at the peak instead of escaping through gaps. You’re still going to freeze when it gets really cold, Otto predicted. Wait until it hits 2030 below. Then we’ll see. The test came on December 7th, 1879, and it was more brutal than anyone had anticipated. A massive cold front swept down from Canada, dropping temperatures across Dakota territory to levels that shocked even the old-timers who’d lived through the winter of 1856.

The thermometer at the military fort 20 mi south read 38 below zero on the morning of December 8th. Some claimed it had hit 45 below overnight, though there was no reliable way to measure temperatures that extreme with the equipment available. It was the kind of cold that killed without mercy. Trees split open with sounds like gunshots, the frozen sap expanding and tearing the wood apart.

A cup of water thrown into the air froze before hitting the ground, landing as a cloud of ice crystals that hung in the air for a moment before settling. Livestock froze, standing up in their barns despite straw bedding and shelter. People woke to find their water buckets frozen solid, their breath frosting on the inside of windows in an inch thick layer, their own eyelashes freezing together if they stepped outside for more than a minute.

At the Henderson Place, 2 mi east, the cabin’s roof partially collapsed on the second night. The weight of snow and ice combined with wood that had become brittle from the extreme cold caused three of the main support beams to snap simultaneously. James Henderson and his wife managed to grab their two children and break through a window, but they lost everything else.

They walked through 40 below temperatures in nightclo to reach the nearest neighbor. a journey of half a mile that left James with frostbitten feet and his wife with frost bitten hands. The elderly Swenson couple who lived alone in a small saudi 4 mi north didn’t survive. Neighbors found them 3 days later frozen in their bed where their fire had gone out sometime during the first night.

They’d apparently been too weak to get up and restart it. A young woman named Margaret Olsen died trying to reach her barn to tend to a cow that was carving. She made it 50 yards from her cabin before the cold took her. Her husband found her body the next morning, frozen solid, one arm outstretched toward the barn she never reached.

A 5-year-old boy in a family to the south died from what his parents thought was just severe cold symptoms. The doctor who examined him later said it was likely carbon monoxide poisoning from a stove that wasn’t venting properly. The family had sealed their cabin so tight against the cold that the bad air had no way to escape. Four people dead in 3 days.

Dozens more with severe frostbite that would cost them fingers, toes, or worse. Livestock losses in the hundreds across the settlement. cabins damaged or destroyed by the weight of accumulated snow and ice. And through it all, Samuel Brandt kept the fire going continuously in his cabin’s central stone fireplace. He designed the fireplace specifically for the arched structure, a large stone base built from rocks he’d hauled from the creek, with a chimney made from stacked stones and clay mortar running straight up through the peak of the iron roof.

The design meant heat rose naturally to the highest point of the arch and then radiated outward and downward, filling the space more efficiently than a conventional fireplace would. The iron roof, which everyone had predicted would make the cabin freeze, was actually helping in ways Samuel hadn’t fully anticipated.

During the day, any weak sunlight that penetrated the clouds would warm the dark metal slightly, and that warmth would transfer down through the insulation to the interior. At night, the metal would lose heat rapidly, but the thick layer of mud straw insulation underneath prevented that heat loss from reaching the living space. The arched shape meant snow piled on top of the iron acted as additional insulation rather than sliding off immediately.

2 ft of snow created an extra barrier between the interior and the killing cold outside. The cabin’s interior temperature with the fire going continuously stayed remarkably stable around 48 to 50°. Not warm by any comfortable standard. Everyone wore coats inside. They could see their breath if they were more than a few feet from the fire, but livable.

Critically, survivably livable. Samuel’s family could breathe normally without their lungs burning from super cold air. Their water didn’t freeze solid in the bucket. The children weren’t developing frostbite from sleeping in below freezing temperatures. Greta could do basic household tasks without her hands going numb and useless.

Compare that to what was happening just 200 yards away at Otto Zimmerman’s cabin. Otto’s family spent three days huddled around their cast iron stove, burning every piece of spare wood they had, and then starting in on furniture. They burned a chair on the second day, a small table on the third day.

They discussed burning one of the bed frames, but decided they couldn’t afford to lose a bed. The interior temperature in their cabin never rose above 28° despite the roaring fire. At one point, it dropped to 22°. Water froze solid in buckets despite being next to the stove. Their youngest daughter, 6-year-old Helga, developed frostbite on three of her toes from sleeping in temperatures that barely registered above freezing.

The toes turned white, then gray, then black. The doctor would later amputate two of them. Otto himself suffered frostbite on his left hand when he had to go outside to bring in more firewood from the stack. He was outside for maybe 90 seconds, and that was enough. Three fingers on his left hand went numb and stayed numb for hours, eventually developing the telltale white and gray discoloration that meant tissue death.

He would lose partial function in those fingers for the rest of his life. The Henderson family, who lived 2 mi east, had their cabin’s roof partially collapse under the combined weight of snow and ice. They survived only because they managed to break through to a neighbor’s cabin and crowded in with another family. Four people in the county died during that cold snap.

An elderly man froze in his sleep when his fire went out. A woman died trying to reach her barn to tend livestock. Two children died when their cabin’s chimney fire went out, and carbon monoxide from incompletely burned wood poisoned them. Samuel’s family survived in relative comfort. When the cold finally broke on December 11th, Otto Zimmerman came to visit.

He looked exhausted. His face was windburned, his hands wrapped in cloth bandages from frostbite, his eyes red from smoke and lack of sleep. He stood outside Samuel’s bizarre iron roofed cabin, looking at the structure he’d mocked 6 months earlier, and said nothing for a long moment. “How cold did it get inside?” he finally asked. “48 to 50° with the fire going.

” “48,” Otto’s voice was flat. “We were at 28° at best. Burned through two months worth of firewood in 3 days. My daughter has frostbite and you’re telling me you were comfortable at 48. I wouldn’t say comfortable. Don’t. Otto held up a hand. Don’t be modest. You stumbled into something that works.

That damned ugly pile of scrap metal and mud just saved your family while the rest of us nearly froze to death. Word spread through the settlement faster than fire. The German immigrant with the strange iron roofed cabin had survived the worst cold snap in memory in better condition than people in conventional structures. People who’d been burning furniture and suffering heard that Samuel’s family had been able to sleep without waking up shivering.

By Christmas, Samuel had five families asking for details. How much had the iron cost? Where had he bought it? How had he attached it? Could they see the inside? He showed them. Showed them the double walls with mud insulation, the curved wooden frame, the overlapping iron plates, the central fireplace designed to heat the arch space efficiently.

They looked at the rusty metal roof, the unusual low walls, the strange shape, and they saw something different now. They saw shelter that worked. Otto showed up in January with a proposition. I want to build one. I’ll buy the iron in Omaha if you help me with the construction. I can’t do another winter like that last one.

The iron costs more now, Samuel warned. Prices went up. You’re looking at maybe $18 for enough plates. I’ll find the money. Can you help? Yes. By spring 1880, three families in the settlement were building iron roof structures based on Samuel’s design. Not all of them worked perfectly. One family didn’t insulate properly and found the cabin too cold.

Another built the arch too steep and had problems with the wooden frame splitting. But Samuel helped troubleshoot the issues, sharing what he’d learned through trial and error. The design evolved. Some builders used corrugated metal roofing material instead of hull plates, which was lighter and easier to work with. Some incorporated the arch into barn designs for livestock.

Some built the walls taller and made the arch less pronounced, creating structures that looked more conventional from the outside, but the core principle remained. Arched metal roof over insulated walls designed to shed snow and wind while holding heat inside. Samuel lived in that cabin for 26 years until 1905 when he and Greta were able to afford a larger house built with proper mil lumber and modern materials.

But he kept the original iron roofed structure and used it as a workshop and storage building. During the brutal winter of 1887, another season of extreme cold that killed livestock and destroyed buildings across Dakota. Samuel’s old iron roofed cabin sheltered three families whose own structures had failed.

14 people crowded into a space meant for four, but they all survived because the cabin held heat while conventional buildings around them froze. Samuel Brandt died in 1912 at 74, having homesteaded the same land for 33 years. The large house he’d built in 1905 burned down in 1923 from a chimney fire, but the iron roofed cabin still stood.

The metal had rusted through in places. The wooden frame had rotted in sections, but the basic structure remained solid. The new owner patched it with whatever materials were available and continued using it for storage. The cabin was finally torn down in 1954, 75 years after its construction, when the property was sold to developers who wanted to clear the land.

The iron plates were sold as scrap metal again and probably melted down for some other purpose, but photographs exist. Black and white images from the early 1900s showing a bizarre structure with low walls and a massive arched metal roof looking utterly out of place on the Dakota prairie. Looking like nothing else built in that era because it was nothing else.

It was one man’s desperate innovation created because traditional methods were killing his family. It was scrap metal and mud and saplings bent into an arch assembled by a German immigrant who’d never built anything more complex than a chicken coupe. And it worked. In the worst winters Dakota territory could throw at it, using only wood fires for heat and mud for insulation.

It kept a family alive and warm when conventional cabins were freezing. The mockery turned to respect. The ugly scrap pile became the model others copied. The crazy German immigrant became the man who’d figured out how to survive Dakota Winters. And somewhere in the historical record, buried in county archives and old journals, there are notes about the unusual winter of 1879 when temperatures hit 45 below and four people died from the cold.

But the Brandt family with their strange metal roofed cabin stayed warm and safe while their neighbors froze. Sometimes the thing everyone laughs at is the thing that saves you when nothing else